Best Of The Best Tips About How To Avoid Undercut Thin Wavy Hairstyles For Medium Length

Use the right current :

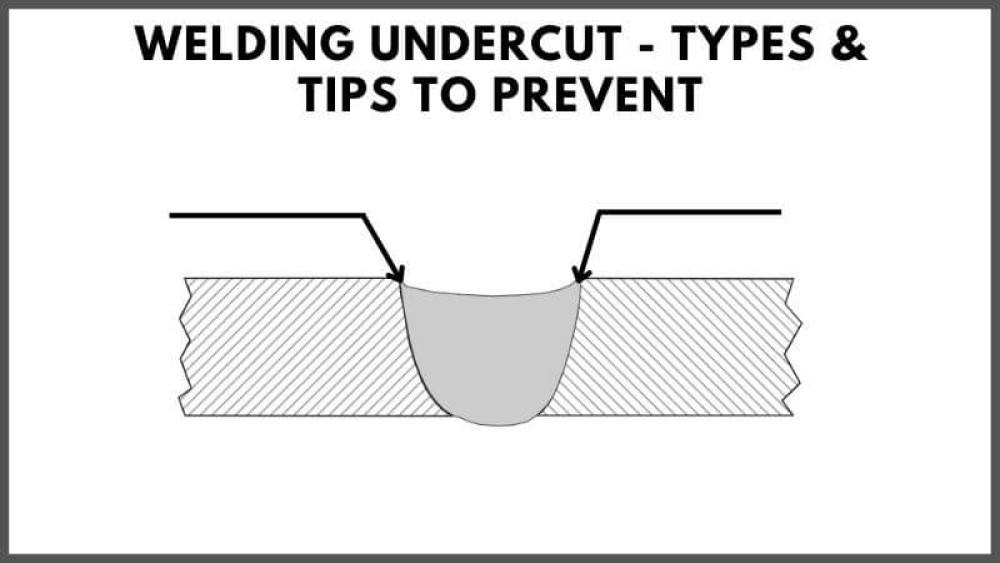

How to avoid undercut. We adjust welding parameters and techniques to prevent undercuts during welding. We explain what undercutting is, as well as list its common causes and ways to fix and avoid it in future. Consider which electrode you are using.

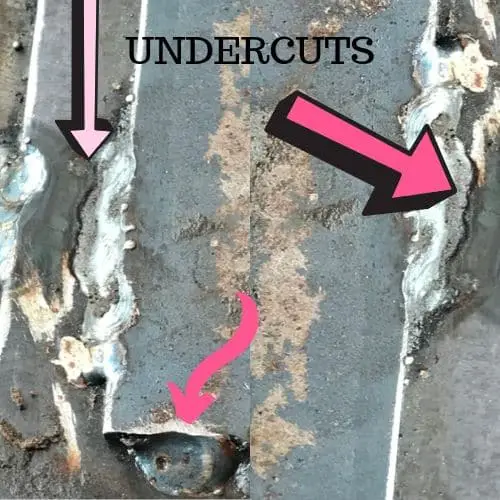

#welding #welddotcom #undercutbeau goes over how to prevent undercut in your welds. Let's dive into what causes undercut and how you can avoid it to maintain the highest quality in your welding tasks. It occurs when the weld is not as strong as it should be and causes problems with the strength of the weld.

June 21, 2024 6:00 am. In this article, we shall be discussing the 7 possible ways to prevent the undercutting welding problem. Pause at both sides of the.

Undercut or undercutting is a weld defect that results in the reduction of the thickness of a material that’s being welded. What is undercut in welding? Here is a list to help you avoid creating craters in your next welding job.

They are grooves or notches that occur in areas close to the junction zones of the welding seam and the welding base metal and parallel to. Doing this reduces overheating to get proper fusion. At the same time, the use of incorrect shielding gas, incorrect welding angle, wrong welding technique, and position are some of the primary causes of this welding flaw.

How to avoid undercut in welding? We get this question often in our dm's and on the forum. There are several ways to prevent welding undercut, including proper welding technique, proper wire feed speed, and proper root opening.

Causes of undercutting | type of undercut | how to prevent undercutting | electrode & shielding | prevention checks for undercutting | faq. Undercut is caused by too much heat, which causes the wire to burn through or vaporize. Too much heat will melt your base materials.

As yena engineering, in our topic today, we will talk about what undercut welds, how they occur, and how to prevent them. Undercutting is one of the most common welding defects. Allow the base metal to cool.

On this episode we tackle the problem of undercut and how to avoid it 0:0:00 intro 0:2:48 welding 0:8:07 results 0:9:15 solutions to undercut 0:10:27 why undercut is a problem. Laura mercier secret brightening powder for under eyes. Always let your base metal cool down.

Here are some tips to improve your welding and prevent undercut defects. Slow down the travel speed. How to prevent undercut in welding you are well aware of what is undercut in welding, now take a look at preventions.

![[HELP] Light Product to Apply Daily to Keep Undercut Somewhat in Place](https://haircutinspiration.com/wp-content/uploads/Taper-Fade-Brushed-Back-Undercut.jpg)

![90 Best Undercut Hairstyles for Men [2020 Styling Ideas]](https://machohairstyles.com/wp-content/uploads/2015/11/12071070_605516576253040_1799542237_n.jpg)